UN presse à comprimés est un dispositif mécanique spécialement conçu pour comprimer des matériaux secs granulaires ou en poudre en comprimés par pression.

Il est largement utilisé dans de nombreuses industries telles que les produits pharmaceutiques, alimentaires, chimiques et cosmétiques, et est principalement utilisé pour produire des comprimés, des comprimés de sucre, des comprimés de calcium, des comprimés de chewing-gum, des comprimés d'assaisonnement, des comprimés de catalyseurs et d'autres produits.

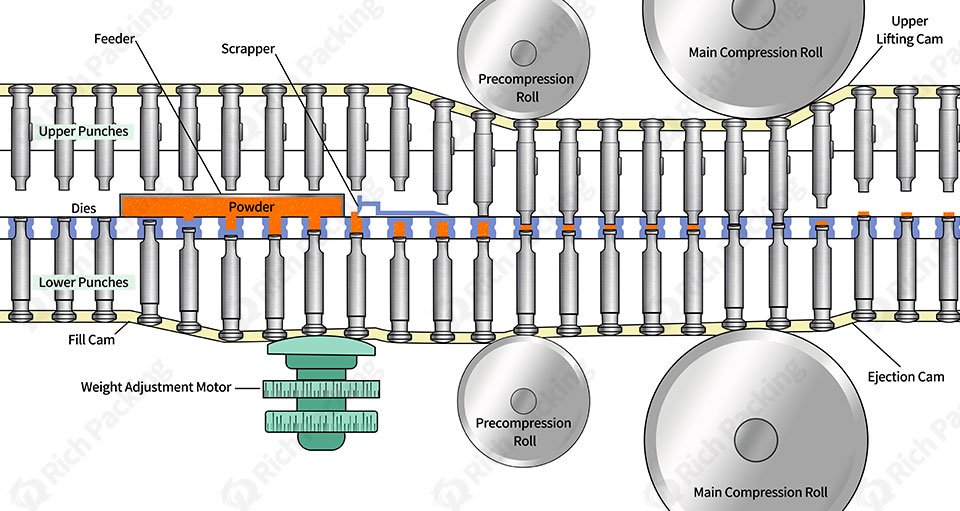

Le principe de fonctionnement de base de la presse à comprimés est de comprimer le matériau dans le moule à travers une ou plusieurs paires de poinçons (poinçons supérieurs et inférieurs), puis de former des comprimés de même taille et de même forme.

Le matériau est d'abord introduit dans le moule par le dispositif d'alimentation. Les poinçons supérieur et inférieur se déplacent ensuite verticalement l'un par rapport à l'autre, appliquant ainsi une pression sur le matériau pour l'extrusion. La forme et la taille du matériau comprimé dépendent des différentes personnalisations du moule. Après compression, le comprimé est éjecté du moule pour former une décharge. Le processus suivant nécessite généralement la connexion d'un tamis à comprimés pour le dépoussiérage et le polissage, ainsi que d'un détecteur de métaux pour rejeter les comprimés hors normes, ce qui facilite le conditionnement ultérieur des comprimés. Par exemple, la connexion d'une machine de comptage de comprimés pour le comptage et la mise en bouteille, et d'une machine de conditionnement sous blister pour le conditionnement sous blister, est également nécessaire.

Presse à comprimés à poinçon unique : généralement utilisée dans les laboratoires ou la production en petits lots, elle utilise un mécanisme de bielle à came ou à roue excentrique pour permettre aux poinçons supérieurs et inférieurs de produire un mouvement relatif pour presser les comprimés.

Multi-poinçon presse à comprimés rotative :Ce type de presse à comprimés entraîne plusieurs moules pour effectuer un mouvement alternatif vertical via une table tournante rotative pour obtenir un processus de compression continu, qui convient à la production de lots moyens à grands.

Presse à comprimés à grande vitesse : Presse à comprimés rotative à grande vitesse : Similaire à la presse à comprimés rotative, mais le plateau tournant a une vitesse de rotation plus élevée, ce qui peut atteindre une efficacité de production très élevée et convient à la production industrielle à grande échelle.

Presse à comprimés à usage spécial : telle que la presse à comprimés à double couche, la presse à comprimés de forme spéciale, etc., sont utilisées pour produire des comprimés avec des formes ou des structures spéciales.

Les presses à comprimés fabriquent une grande variété de produits dans différents secteurs. Voici quelques exemples précis :

Il s'agit du domaine le plus utilisé pour les presses à comprimés, principalement pour la fabrication de comprimés pharmaceutiques, notamment de comprimés ordinaires, de comprimés à libération contrôlée, de comprimés effervescents, etc.

Produits typiques

Comprimés ordinaires : Il s’agit de la forme de comprimés la plus courante, couvrant un large éventail de catégories.

Comprimés à libération contrôlée : ce type de comprimé est conçu pour une libération lente de médicaments afin de prolonger la durée d'action des médicaments dans l'organisme et de réduire le nombre de médicaments, tels que les médicaments pour la gestion des maladies chroniques, comme les médicaments pour le traitement du diabète.

Comprimés effervescents : Contenant du bicarbonate de sodium et des acides organiques, ils réagissent au contact de l'eau pour produire du dioxyde de carbone. Ils sont souvent utilisés dans les médicaments contre le rhume, les troubles digestifs, etc., pour augmenter la solubilité et l'absorption des médicaments.

Avec l’essor et la popularisation du concept de santé, la demande de presses à comprimés dans l’industrie des produits de santé augmente également.

Produits typiques

Comprimés de vitamines : tels que les comprimés de vitamine C et les comprimés multivitaminés, qui sont utilisés pour compléter les vitamines qui peuvent manquer dans l’alimentation quotidienne.

Comprimés minéraux : tels que les comprimés de calcium et les comprimés de fer, qui sont utilisés pour compléter les minéraux nécessaires au corps humain et prévenir l'ostéoporose, l'anémie, etc.

Comprimés d’extraits de plantes : tels que les comprimés de ginseng et les comprimés de ganoderma, qui utilisent les ingrédients médicinaux des plantes pour renforcer l’immunité ou aider au traitement de certaines maladies.

La demande de presses à comprimés dans l'industrie alimentaire se reflète principalement dans les exigences de sécurité particulières des équipements, ainsi que dans la flexibilité, qui doit répondre aux besoins de production de pouvoir changer rapidement de moules pour s'adapter à différents produits.

Produits typiques

Bonbons durs : menthes de différentes formes et tailles, bonbons aux fruits, etc.

Tablettes de lait et tablettes de chocolat : telles que les tablettes de lait en bonbon, les tablettes de chocolat au lait, etc.

Boissons solides et condiments : tels que les comprimés de café instantané, les comprimés de thé, etc.

Tablettes de condiments de cuisine : telles que les blocs d'essence de poulet, les blocs d'assaisonnement.

Aliments spéciaux : tels que biscuits compressés, barres énergétiques, etc., qui sont généralement utilisés comme aliments portables lors d'aventures en plein air ou d'opérations militaires.

Des presses à comprimés à haute résistance à la corrosion, à haute température, antidéflagrantes et de sécurité ont été appliquées dans l'industrie chimique.

Produits typiques

Comprimés de catalyseur : Comprimés de catalyseur utilisés dans les procédés chimiques tels que le raffinage du pétrole, l'ammoniac synthétique, le caoutchouc synthétique, etc., tels que les comprimés de catalyseur au nickel, les comprimés de catalyseur au molybdène, etc.

Comprimés d'engrais : utilisés dans la production agricole, tels que les comprimés d'engrais azotés, les comprimés d'engrais phosphatés, les comprimés d'engrais potassiques, etc., qui sont pratiques pour les agriculteurs à appliquer à la demande.

Voici la classification actuelle des principales applications des presses à comprimés. Avec les progrès technologiques constants, leur champ d'application et les types de produits fabriqués s'élargiront.

Dans le contenu ci-dessus, nous avons brièvement présenté les différents types de presses à comprimés. Le choix d'une presse à comprimés adaptée aux besoins réels, afin d'améliorer l'efficacité de la production, de garantir la qualité des produits et de réduire les coûts, repose sur les facteurs clés suivants.

1. Demande de production

Rendement et échelle

La première étape du choix consiste à définir clairement le volume de production attendu. Pour les laboratoires et les petites productions, l'achat de presses à comprimés manuelles ou à poinçon unique est une solution adaptée. Pour une production continue à grande échelle nécessitant une amélioration de l'efficacité, il est nécessaire d'opter pour des presses à comprimés rotatives multi-poinçons, à grande vitesse et entièrement automatiques.

Types de produits sous forme de comprimés

Les exigences en matière de comprimés varient selon les industries. Par exemple, l'industrie pharmaceutique se concentre sur la consistance, la dureté et le temps de libération prolongé des comprimés ; l'industrie agroalimentaire accorde davantage d'importance au goût et à l'apparence des comprimés. Par conséquent, l'applicabilité de la presse à comprimés doit être adaptée aux caractéristiques du produit.

Plage de pression

La pression de la presse à comprimés est un paramètre essentiel qui détermine le type de matériaux à traiter et la dureté des comprimés. Comprendre la pression de compression optimale du matériau et choisir le modèle de machine adapté sont essentiels pour garantir la qualité des comprimés.

Moules personnalisés

Les moules personnalisés sont essentiels pour obtenir la taille et la forme des comprimés, et les paramètres clés sont le diamètre et l'épaisseur du comprimé. Bien que la presse à comprimés soit une machine polyvalente, différents comprimés peuvent être produits en remplaçant différents moules. Cependant, la taille et le nombre de moules que le plateau tournant peut accueillir sont des critères essentiels.

Niveau d'automatisation

Pour les moyennes et grandes entreprises, la production de lots moyens et grands et la production en usine pharmaceutique, il est recommandé de choisir une presse à comprimés hautement intelligente et automatisée, afin de réduire l'intervention manuelle, de réduire les coûts de production et d'améliorer la précision et la cohérence de la production.

Entretien et nettoyage

Dans les industries pharmaceutique et agroalimentaire, les presses à comprimés garantissant le respect des normes d'hygiène du processus de production sont de plus en plus populaires. Le respect de normes d'hygiène strictes exige une machine facile à entretenir et à nettoyer.

Les presses à comprimés haut de gamme ont réalisé une opération PLC à un seul bouton pour soulever le plateau tournant et le déplacer automatiquement vers l'extérieur de la machine, de sorte que l'opérateur peut facilement retirer le moule pour le nettoyage et l'entretien, ce qui réduit complètement les temps d'arrêt et réduit les coûts de maintenance.

Durabilité

Le plateau tournant et le moule de la presse à comprimés sont des pièces constamment soumises aux chocs et aux frottements lors de son fonctionnement prolongé. Afin de réduire les coûts d'exploitation à long terme, la durée de vie de ces deux pièces est primordiale. Le plateau tournant de la presse à comprimés que nous fabriquons est forgé en fonte ductile QT600. Après 12 mois de détente interne, il est stable comme neuf, même après plus de dix ans d'utilisation. Le moule est en GCR15, un matériau résistant à l'usure, à la pression et à la corrosion, qui permet d'obtenir facilement des diamètres et des épaisseurs de comprimés plus importants.

Normes et certifications de l'industrie

Lors de l'achat d'une presse à comprimés, assurez-vous qu'elle est conforme aux normes industrielles en vigueur, telles que les BPF (Bonnes Pratiques de Fabrication). Pour une utilisation sur le marché européen, la machine doit être conforme aux normes CE, RoHS, CEM, LVD, etc. Les exigences du marché nord-américain sont les plus strictes. Outre les normes mentionnées ci-dessus, vous devez non seulement obtenir la certification FDA, mais également choisir une presse à comprimés certifiée UL et CSA.

Sécurité du matériel

La presse à comprimés doit être équipée de dispositifs de sécurité complets, tels que plusieurs boutons d'arrêt d'urgence pour assurer la sécurité des opérateurs, des écrans d'isolation pour isoler les matériaux de la contamination croisée avec l'environnement extérieur, etc.

Réputation du fournisseur

Le choix d'un fournisseur de fabrication professionnel avec une bonne réputation sur le marché et un réseau de nombreuses années d'expérience dans l'industrie peut vous fournir une assistance rapide et efficace dans l'installation, la mise en service, la maintenance et les mises à niveau des équipements.

Implantés dans les secteurs pharmaceutique et de l'emballage en Chine depuis plus de 30 ans, nous disposons d'un capital social de 10 millions de yuans. Nos principaux produits couvrent l'ensemble du processus de préparations solides, notamment les géluleuses, les presses à comprimés, les lignes de production de flacons multi-comprimés, les machines de conditionnement sous blister et les encartonneuses automatiques à grande vitesse. Nous disposons de centres de service à Hong Kong, en France et aux États-Unis. Grâce à la qualité supérieure de nos machines et à notre service irréprochable, nous avons noué des partenariats durables avec des entreprises du Fortune 500, dont GSK, UCB, USPharma et Robison-Pharma.

Si vous souhaitez trouver un fournisseur de presse à comprimés fiable, nous attendons avec impatience votre contact avec nous et espérons devenir votre fidèle ami et partenaire.

Formation et documentation

Votre fournisseur de fabrication de machines doit fournir des manuels d'utilisation et des vidéos détaillés ainsi que la formation opérationnelle nécessaire pour garantir que les utilisateurs peuvent pleinement comprendre les différentes fonctions de l'équipement ainsi que les directives d'utilisation et d'entretien quotidiennes.

Sur le marché actuel, notamment en Chine, peu de fournisseurs proposent des manuels d'utilisation et des guides vidéo standardisés. C'est la situation actuelle. En cas de problème avec une machine, il est impossible de le résoudre immédiatement et il faut contacter le fournisseur. L'attente et les connexions à distance sont longues, ce qui impacte l'efficacité de la production et augmente les coûts liés au temps.

Notre entreprise dispose d'une équipe technique et de recherche et développement forte de 21 ans d'expérience. Nous proposons des manuels d'utilisation et d'entretien standard et détaillés, ainsi que des vidéos de configuration, en chinois et en langues étrangères, pour tous nos modèles. Notre objectif est d'offrir à nos clients un service irréprochable.

En tant qu'équipement de production, le choix d'une presse à comprimés n'est pas simple. Il nécessite une réflexion approfondie, tenant compte des besoins spécifiques et de la compétence du fournisseur. Grâce à cette présentation des applications et des types de presses à comprimés utilisés dans divers secteurs, nous espérons vous apporter les connaissances nécessaires pour prendre une décision plus éclairée et raisonnée. Pour toute autre question, n'hésitez pas à nous contacter. Contactez-nous .