Dans l'industrie pharmaceutique, la précision et l'efficacité du comptage des comprimés sont cruciales. L'introduction de compteurs automatiques de pilules Peut améliorer considérablement l'efficacité des lignes de production pharmaceutique. Cet article explore les avantages des compteuses automatiques de comprimés pour l'industrie pharmaceutique, notamment une précision accrue, une productivité accrue et une réduction des coûts de main-d'œuvre. Nous aborderons également le choix du bon compteur, les étapes d'installation et d'intégration aux lignes de production existantes, ainsi que les défis et solutions potentiels. Enfin, nous présenterons les différents types et principes de fonctionnement des compteuses automatiques de comprimés, vous permettant ainsi de comprendre pleinement comment ces appareils peuvent optimiser votre processus de production.

Les compteurs automatiques de comprimés utilisent des capteurs avancés, une technologie photoélectrique et une technologie de détection visuelle de pointe pour garantir un comptage précis de chaque comprimé. Cette méthode de comptage de haute précision réduit non seulement les erreurs humaines, mais garantit également la cohérence et la qualité de chaque lot de médicaments. Ceci est particulièrement important dans l'industrie pharmaceutique, où un comptage précis des comprimés influence directement le dosage, l'efficacité et la rentabilité du médicament.

Les compteurs automatiques de comprimés peuvent considérablement améliorer l'efficacité des lignes de production d'emballages pharmaceutiques. Les méthodes de comptage manuelles traditionnelles sont non seulement chronophages et exigeantes en main-d'œuvre, mais aussi sujettes aux erreurs. Les compteurs automatiques, quant à eux, peuvent fonctionner en continu, sans interruption, améliorant considérablement la vitesse et l'efficacité de la production d'emballages pharmaceutiques. Cela permet non seulement de raccourcir le cycle de production, d'accroître la stabilité des produits et d'être bénéfique pour l'entreprise, mais aussi de répondre à la forte demande de médicaments et de conquérir rapidement des parts de marché.

L'utilisation de compteurs automatiques de pilules peut réduire considérablement les coûts de main-d'œuvre. L'équipement automatisé remplace le comptage manuel ou semi-automatique fastidieux, réduisant ainsi la dépendance aux opérations manuelles. Cela réduit non seulement les coûts de main-d'œuvre, mais aussi la charge de travail des employés, diminuant ainsi le risque de maladies professionnelles liées au travail répétitif.

Les équipements de comptage de base sont principalement utilisés sur les lignes de production de petite et moyenne taille, se caractérisant par leur simplicité et leur fiabilité. Ces appareils utilisent généralement des capteurs photoélectriques et des plaques vibrantes standard pour contrôler la transmission des comprimés. Les capteurs détectent le nombre de comprimés, qui sont ensuite automatiquement mis en bouteille. La productivité varie généralement de 10 à 35 comprimés par minute.

Caractéristiques

Opération simple : convient à la production à petite échelle.

Faible coût : idéal pour les entreprises disposant de budgets limités.

Entretien facile : structure simple, facile à entretenir et à nettoyer.

Les compteuses automatiques de pilules de milieu de gamme conviennent aux lignes de production de moyennes et grandes tailles, offrant davantage de fonctionnalités et une précision accrue. Ces appareils sont généralement équipés de capteurs avancés et de systèmes de contrôle intelligents, capables d'effectuer des tâches de comptage plus complexes. Elles peuvent détecter et rejeter les produits défectueux en évaluant la taille du matériau. Leur cadence de production est généralement comprise entre 85 et 100 flacons par minute. Ces compteuses peuvent traiter non seulement les pilules, mais aussi les comprimés et les gélules.

Caractéristiques

Haute précision : utilise une technologie de détection avancée pour garantir la précision du comptage.

Multifonctionnel : capable de gérer différents types et tailles de pilules.

Haute automatisation : comprend des fonctions d'étalonnage automatique et de diagnostic des pannes.

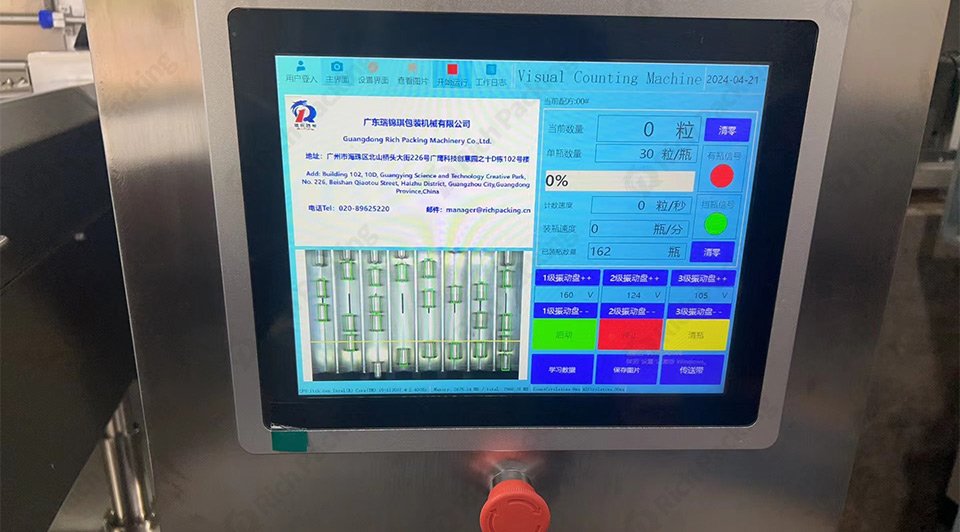

Les compteuses automatiques de comprimés haut de gamme sont conçues pour les lignes de production à grande échelle et bénéficient d'une technologie de pointe et d'une précision optimale. Le comptage visuel améliore considérablement la précision, la rapidité et la détection des défauts. En augmentant le nombre de canaux de comptage, passant de 8 à 16/24/48, l'efficacité de la production répond aux besoins de la production d'emballages à grande échelle. Ces compteuses s'intègrent parfaitement aux autres équipements de la ligne de production pour une automatisation complète.

Caractéristiques

Ultra-haute précision : répond aux normes pharmaceutiques les plus strictes.

Comptage à grande vitesse : adapté à la production efficace à grande échelle.

Contrôle intelligent : Comprend des fonctions de surveillance à distance et d'analyse des données, prenant en charge la gestion intelligente des lignes de production.

Le principe de fonctionnement des compteuses automatiques de pilules repose principalement sur la technologie des capteurs photoélectriques. Les pilules passent par un système de tri par vibrations pour garantir leur intégrité et leur distribution uniforme dans la zone de comptage. Des capteurs détectent chaque pilule passant et transmettent des signaux au système de contrôle. Ce dernier, basé sur des exigences de comptage prédéfinies, contrôle la quantité de pilules produites et conditionnées.

Étapes principales

1. Alimentation des pilules : les pilules sont alimentées uniformément dans la zone de comptage grâce au système de tri par vibration.

2. Détection de comptage : les capteurs détectent le passage des pilules et enregistrent les données de comptage.

3. Traitement des données : Le système de contrôle traite les données de comptage et contrôle la sortie des pilules.

4. Sortie d'emballage : les pilules sont sorties vers l'équipement d'emballage en fonction des exigences de comptage prédéfinies.

Précision

La précision est un critère essentiel lors du choix d'un compteur de comprimés. La précision et les méthodes de comptage varient selon les modèles de compteurs automatiques. Les compteurs haute précision garantissent un comptage précis de chaque lot de médicaments et l'élimination des produits défectueux, garantissant ainsi le respect des normes strictes de l'industrie pharmaceutique.

Vitesse

La vitesse du compteur automatique de pilules est un autre facteur clé. L'efficacité de la ligne de production est étroitement liée à la vitesse de comptage du compteur. Choisissez une vitesse de comptage adaptée aux besoins de production actuels et aux perspectives de croissance, garantissant ainsi une production efficace sans surcharger l'équipement.

Options de personnalisation

Les lignes de comptage automatique de comprimés ont des besoins différents, d'où l'importance des options de personnalisation. Les compteurs haut de gamme peuvent être personnalisés en fonction des types de comprimés et des exigences de production, notamment en adaptant les modes de comptage, le rejet des défauts, la détection du poids, les systèmes d'alarme et l'intégration avec d'autres équipements de production.

Lors de l'installation d'un compteur automatique de pilules, tenez compte de sa compatibilité avec les équipements de production et les logiciels existants. Assurez-vous que le compteur puisse s'intégrer parfaitement à la ligne de production existante afin d'éviter toute interruption de production due à une incompatibilité des équipements. Généralement, des équipes techniques professionnelles assurent l'installation et le débogage du compteur pour garantir son bon fonctionnement.

Étapes d'installation

1. Sélection et préparation du site : Choisissez un emplacement d'installation approprié, en vous assurant qu'il y a suffisamment d'espace pour le fonctionnement et l'entretien du compteur.

2. Connexion de l'équipement : connectez le compteur à d'autres équipements de la ligne de production, y compris les convoyeurs et les machines d'emballage.

3. Débogage du logiciel : installez et déboguez le système logiciel du compteur, en garantissant la compatibilité avec le système de gestion de production existant.

4. Essai : effectuez un essai pour vérifier l'état de fonctionnement de l'équipement et la précision du comptage, en vous assurant que tout est normal avant la production officielle.

Divers problèmes techniques peuvent survenir lors de l'intégration, notamment en ce qui concerne la compatibilité des équipements et les connexions logicielles. Ces problèmes nécessitent l'intervention d'équipes techniques professionnelles pour le débogage et la résolution afin de garantir le bon fonctionnement des équipements.

Exigences en matière de formation des employés

L'introduction d'équipements automatisés nécessite une formation adéquate des employés afin de garantir leur utilisation et leur maintenance correctes. La formation porte notamment sur l'utilisation, le dépannage et la maintenance quotidienne des équipements.

Intégration compteurs automatiques de pilules L'intégration de compteurs automatiques de comprimés dans les lignes de production existantes peut améliorer considérablement l'efficacité et la précision de la production tout en réduisant les coûts de main-d'œuvre. Cependant, le choix du compteur adapté, l'installation et la configuration correctes de l'équipement, ainsi que la gestion des difficultés et des limitations potentielles sont essentiels à une mise en œuvre réussie. Une compréhension approfondie des types et des principes de fonctionnement des compteurs automatiques de comprimés permet aux entreprises d'optimiser leurs processus de production et d'atteindre une production efficace.